Customer Services

Copyright © 2025 Desertcart Holdings Limited

Desert Online General Trading LLC

Dubai, United Arab Emirates

⚡ Unlock your creative edge with precision and power in every carve!

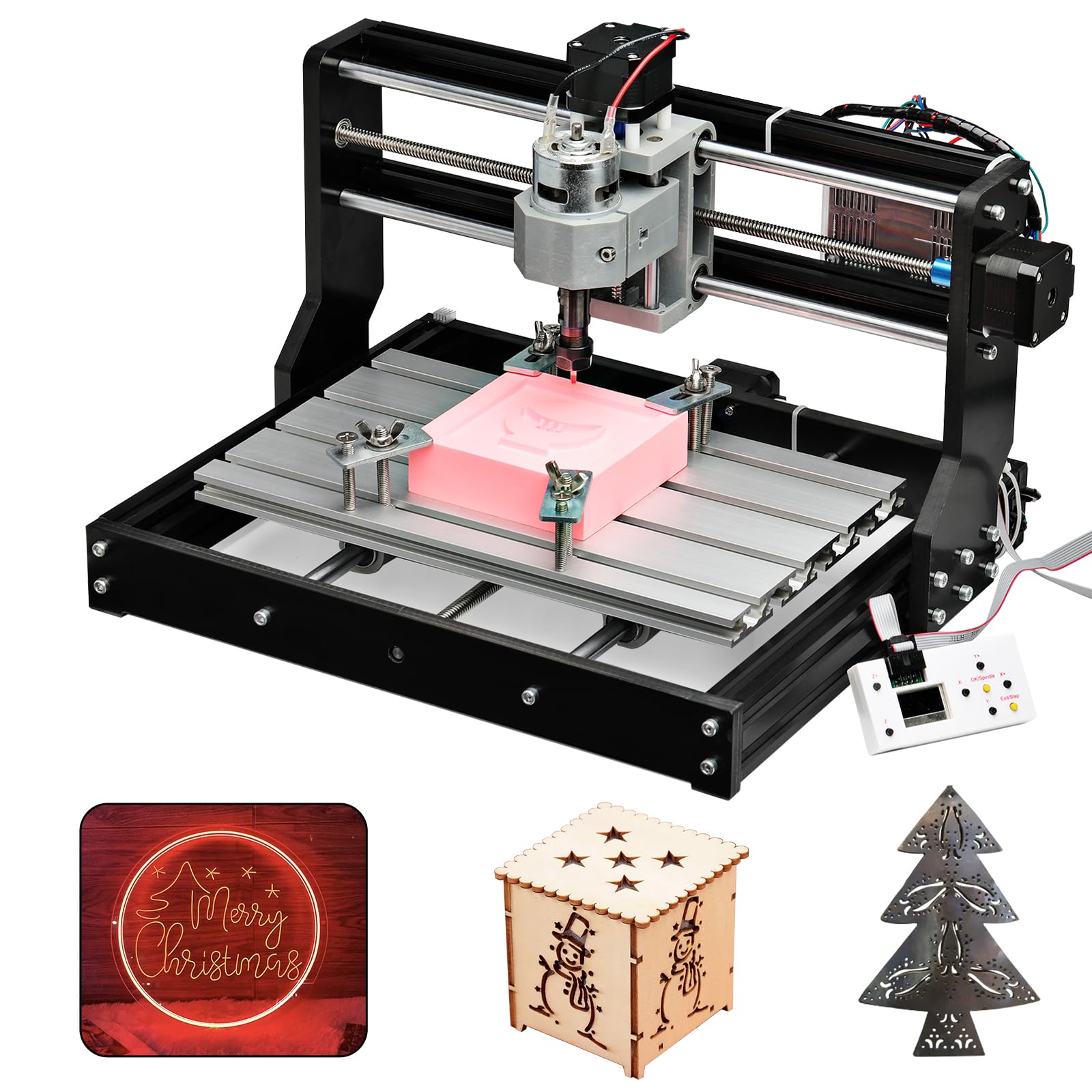

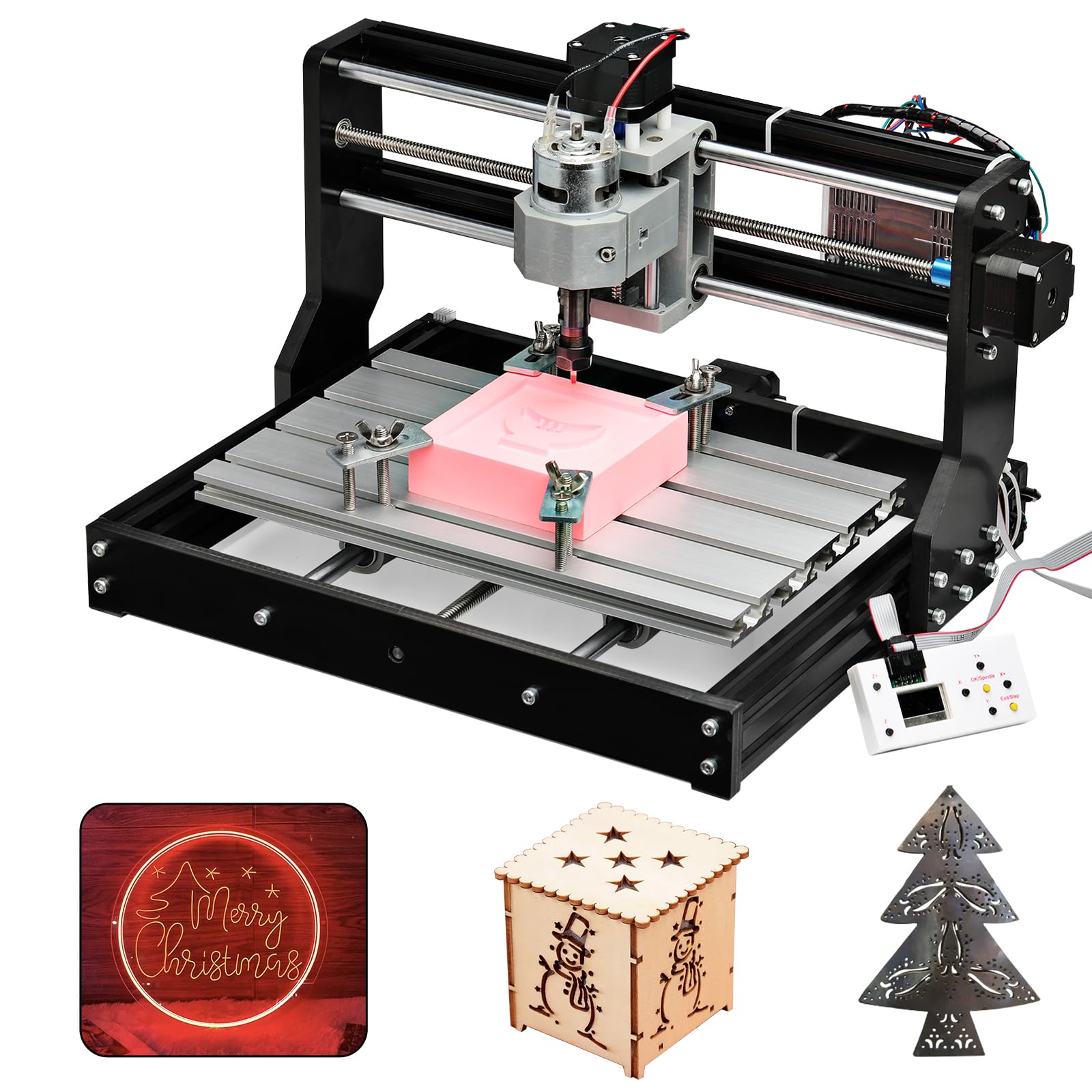

The Genmitsu CNC 3018-PRO is a professional-grade 3-axis router kit featuring a 300 x 180 x 45mm working area, upgraded for easy assembly and enhanced stability. It supports a powerful 20,000 RPM spindle and runs on open-source GRBL software, making it ideal for precise carving, milling, and engraving across a wide range of materials including plastics, soft aluminum, wood, acrylic, PVC, and PCBs. Expandable with optional kits, it’s designed for makers who demand accuracy, speed, and versatility.

| Brand | Genmitsu |

| Power Source | Corded Electric |

| Product Dimensions | 7.09"W x 11.81"H |

| Voltage | 24 Volts |

| Item Weight | 15.3 Pounds |

| Horsepower | 120 |

| Maximum Rotational Speed | 1000 RPM |

| Amperage | 1.3 Amps |

| Base Type | Fixed |

| Global Trade Identification Number | 00816550021620 |

| UPC | 816550021620 |

| Manufacturer | SainSmart |

| Part Number | B07P6K9BL3 |

| Item Weight | 15.3 pounds |

| Item model number | 3018-PRO |

| Style | 3018-PRO |

| Thickness | 0.1 Millimeters |

| Item Package Quantity | 1 |

| Included Components | Wood Carving Milling Engraving Machine |

| Batteries Included? | No |

| Batteries Required? | No |

K**S

My first year learning and using CNC Router Machine

I’ve never used a CNC Machine before purchasing the Genmitsu 3020-PRO MAX, and to be honest I didn’t know if I could figure it out. I have to say that I sure had a lot to learn. Granted I did watch a whole lot of YouTube and seen the different types of machines. The one thing that hooked me was the wood cravings that could be created that as a wood craftsman I could never accomplish with the limited experience I have. I chose this machine over others was first the price, ease of assembly (it comes mostly assembled already) and simplicity of the operation. I purchased my unit in July of 2022 but since I was not ready to start I didn’t open the box till June. Getting the 3020 was pretty easy. Learning the difference softwares and programs was the default part. The box it came in had all the parts and manuals to put it together but was missing a USB stick with the software! At first I was a bit taken back by this and sent an email to the customer service department. This is when I first realized I had made the right choice. A service member (Hong or Mr. Hong) was right on spot with sending me a link to download software. I used a Laptop with Windows 10 and was able to setup the comport and install Candle. A software that uses files called gcode (*.nc file) to tell the machine what to do. Also one of the files was a test file that craved a small 2.5D image. I know this now but didn’t know then that a machine with three axles will only crave 2.5D as the other 0.5 is the flat surface on the bottom. From this one file I was able to figure out the files needed to take a object (2.5D) and turn it into a work of art. To my surprise it actually takes three steps to complete first. 1st was finding the object files. Too my delight in found 1000’s of free files in a *.stl format online. As I’m not going to use these files or creations to sell I downloaded and modified using a software already available in Windows called 3D Build. I then downloaded a trial version of MeshCam. As my CNC machine is located in a spare room, I used another Laptop to modify the files, open these files with MeshCam to create the tool paths and convert the files from an STL file into a NC file that the Genmitsu 3020-PRO MAX uses. I only was able to convert 15 files using MeshCam before the trial version ran out. I have tried other softwares but after using MeshCam I will pay for the license ($250.00 one time payment) as other programs where not as easy to learn and the results as positive. I would have purchased the software already but ran into issues with the stepper motors. I started getting what I first thought was banding with the X and Y axis that increased very quickly, projects halfway completed were being ruined. I emailed Hong and told him my troubles and he sent 2 new stepper motors to me free of charge. I installed the new motors and it’s back to creating beautiful works of art. While the machine was down I was able to give the machine a good cleaning. My only drawback with the machine is that the manufacturer does not at this time offer a explanation kit for this model. I’m hoping one will come out in the near future. Overall I give this one an 4 1/2 Stars. It’s built strong, service is excellent and it’s a very good investment for anyone looking to get into using a CNC Machine.

C**D

Trust yourself and get this

I was just like you, reading reviews and contemplating if I should meander in to the world of CNC machines, a world that I know nothing about. If you're searching for these machines, you're already interested - so the only thing I can tell you is - get it.I have basic knowledge when it comes to electronics/hardware/software, if you're completely new to these things, the setup and usage may be slightly intimidating, but it IS easy enough that anyone can do it by following basic instructions. Like most mention - instruction manuals aren't the easiest to understand (for anything) but there are a ton of user videos all across the interwebs showing you how to set up/run the 3018. (seriously, if you need to learn anything, ever, about anything, ever, just YouTube or TikTok that ish)Out of box - I was a bit anxious. Any time you're opening a package that has hundreds of tiny parts it can seem like an uphill battle. If you dedicate a half hour or so of watching a set up video (all the way through), then setting it up while watching it again, it makes this set up a breeze. I had mine completed in about an hour, and after a minor issue was up and running. The V Bits that come with the machine are what I use most for cutting out designs. I also purchased some straight bits to use which, to me, are necessary if you're cutting out large pockets of material. As far as while this machine is running, people have mentioned noise quite often in reviews. I did not find the noise to be overwhelming. I have the 3018 set up in a room inside my house, and with the door shut, it doesn't disturb us at all.I use a Mac currently. I hate it, I was born and raised on a PC. So far I have found that Easel (it's a free application from inventables) is the easiest and most user friendly application to send G-Code, or your designs, to the machine. It's also incredibly user friendly for creating new designs for your 3018 if you're less than a novice and don't use any number of graphic suites (inkscape, illustrator, photoshop) along with Fusion 360 to create toolpaths for your designs. Windows users have a ton of more options to utilize your machine while connected to a computer, or you can upload your codes to the controller that comes with the machine to create your projects.I have used the 3018 quite often in the month I have had it. As always, there is trial and error involved. There is a learning curve when it comes to types materials to cut/carve at what speeds, and what types of bits to use. As you try a few projects here and there, you'll get much more comfortable about what to cut, and how to cut it. You can research and read about spindle speeds/materials/bits as much as you want, but you'll inevitably learn more from trial and error after having that basic knowledge from your prior research. So far I have mainly used MDF for my projects, though when attempting to use it on acrylic and copper, I can see the vast potential this machine has.CUSTOMER SERVICE for this product awesome. I had an minor issue during set up, and I was sent a replacement part incredibly quick. I was up and running the same week I received the machine. I have seen reviews complaining, but my experience reflects all of the glowing reviews about the help I received.This isn't a plug and play machine. You have to set it up. You have to learn it. At the price point, and with the capabilities this machine has - it is the PERFECT starter machine to get into the world of CNCs. All I can say is that you won't regret this if you try it. I'll upgrade the bed of the machine for larger projects, and eventually invest in the laser module to play with that as well. I would definitely recommend this machine and I would buy it again.

Trustpilot

2 weeks ago

2 months ago