Servicios al cliente

Sobre nosotros

Copyright © 2025 Desertcart Holdings Limited

⚙️ Master the micro, dominate the detail!

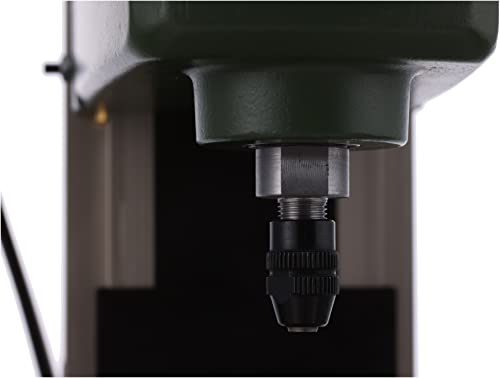

The Proxxon Micromot MF 70 is a compact, 100W milling machine designed for precision model making and small-scale projects. Featuring a sturdy 7kg aluminium frame and adjustable controls for smooth, accurate feed, it excels at delicate milling and drilling tasks with tiny carbide bits. Perfect for professionals and hobbyists who demand fine detail and reliable performance in a space-saving design.

| ASIN | B002H5AH5O |

| Batteries Required? | No |

| Batteries included? | No |

| Battery description | Corded electric |

| Best Sellers Rank | 99,935 in Business, Industry & Science ( See Top 100 in Business, Industry & Science ) 53 in Power Milling Machines |

| Colour | Metal |

| Customer Reviews | 4.4 4.4 out of 5 stars (474) |

| Date First Available | 17 Feb. 2010 |

| Included Components | mini lathe |

| Item Package Quantity | 1 |

| Item Weight | 7 kg |

| Item model number | 27110 |

| Manufacturer | Proxxon Micromot |

| Material | Aluminium |

| Number of Pieces | 1 |

| Part Number | 27110 |

| Power Source | Air-Powered |

| Product Dimensions | 43 x 28 x 24 cm; 7 kg |

| Voltage | 230 Volts |

| Wattage | 100 watts |

M**N

A grand little machine.

I bought this mill for model railway and similar small scale work. My existing milling machine was limited to 2000rpm and it wasn't fast enough for drilling and milling with tiny carbide bits. I spent a couple of hours setting it up and adjusting the gibs and the play in the handwheels. At first the stiffness of the ways varied a lot over the travel, but after repeatedly winding the table end to end and forward and back all was well. I reckon the lead screws had not been evenly lubricated. A dial test indicator helped to show any slop when adjusting the gibs and handwheels. It's a pity that the instruction sheet does not explain how best to adjust these clearances. Only the end two of the three adjustment screws on each slide need setting, Use the centre screw to lock the table when necessary. Some reviewers of this machine have pointed out that the table can distort when work pieces or accessories are clamped to it. While this is indeed so, it is worth bearing in mind that this mill is designed for delicate work,and the forces the machine applies to the work are tiny. When fixing a vice or clamping work to the table, only very gentle tightening is needed to secure the job and prevent movement. All in all it's a cracking little machine for the sort of work I use it for. Baz

T**Y

Great litle machine

Great little milling machine, robust and which works really well. I have used it on plastic and brass with 3mm dia milling cutters. However it is quite small, designed for small modelling projects and as such can only make small cuts, on brass for example about 0.5mm max. depending on the thicknes. It is good for drilling as well enabling slow controlled feed and avoiding any snatching when going through thin materials.

P**R

Handy little machine tool. Good price, but one fault.

For those with limited space and funds this little miller is good value for money. It does have one fault however which is significant if you intend undertaking accurate work. The table (X axis) traverses smoothly and without any free play when the traverse handwheel is rotated. But as soon as a vice, rotary axis or any other fixture is bolted to the table - even with minimum force - the table develops an alarming amount of yaw. This can only be eradicated by adjusting the gibs. Then when you come to remove the fixture you must first slack off the gibs or have the table seize up! So this rather tedious process has to be repeated continuously. Well, I can put up with it, but I think Proxxon should get this problem sorted as it is, otherwise, a nice little machine. The 3mm Proxxon end milling cutters (ref 28722) seem to have a raised central nib on the bottom cutting face. This does not facilitate good machining on metals. I recommend the RS Components 3mm four flute carbide endmills which cut beautifully and are very good value for money. One final little moan, the collets supplied with the MF70 cover a reasonable range of diameters. But the 2,4mm collet is too small for a 2,5mm drill (M3 tapping size - used often) and the 3,0mm is too large. Proxxon - please note!

P**O

strong and sturdy

has the common accessories which allow you to do most jobs, excellent little tool.

T**E

Excellent, but don't get carried away.

Very much a machine for the hobbiest. Do not buy if you require a machine for anything heftier. Produces excellent results on brass or ally, but take small bites and let it take it's time.

C**E

Excellent bit of kit

Excellent and accurate machine as expected from Proxxon.

M**N

Five Stars

Great little machine for what I need it for which is small intricate work

G**S

Good machine, but beware of its limits.

I know this is a small machine, for small work, but there's one thing that drove me nuts with it -- and this is also common to many other machines -- the handwheels are too small a diameter. I am a professional scale modeller & very used to using small and delicate machines, but to get a smooth vertical feed when the gibs are correctly set is difficult. I've made an extension lever for the top feed wheel, which is a huge improvement. The extra leverage means that fine & smooth control is easily possible. I would also like a collet chuck up to 6mm, not for 6mm cutters, but for 6mm shanked small cutters (but that's my problem -- I have many miniature end mills with 6mm shanks). Overall, a good machine but with a definite limit to the materials you can work. It's possible to get good results on brass or aluminium, but only VERY fine cuts can be taken without vibration. Don't attempt to cut steel. With hindsight, I should have gone for the (rather more expensive) FF230 Micro Mill...

P**R

Gekocht voor het affrezen van chips. Mooie compacte frees. Eenvoudig in gebruik.

F**A

Satisfied

D**N

Je l'utilise exclusivement pour l'usinage d'alumium et je la trouve géniale. Je n'ai absolument rien à lui reprocher. Elle est petite, facile à transporter. Pas de jeux lors de la manipulation des verniers en X et Y. Pour l'axe des Z, il y en a quand même un peu. Je n'ai aucun problème pour lui mettre 5 étoiles. Cordialement, David.

A**S

Eine geniale Maschine. Der Kreuztisch ist zwar etwas schwer zu bewegen, dafür hat er auch praktisch kein Spiel. Ich habe noch den kleinen Schraubstock PM40 dazubestellt. Damit kann man dann sehr präzise arbeiten. Allerdings natürlich nur kleine Werkstücke. Die Spannbereiche sind sehr beschränkt. Ich hatte die Aufgabe ein vorhandenes 4,2 mm Loch in 2mm-Alu zum Langloch 4,2 x 5,0 mm aufzufräsen. Dazu muss man natürlich den Fräser genau an einer Seite des Loches positionieren. Aber wie macht man das? Visuell geht nicht. Aber folgender Trick hat besser funktioniert als gedacht: Da Fräser und Werkstück elektrisch isoliert sind, habe ich einfach am Fräser und am Werkstück ein Multimeter angeschlossen und auf Durchgangsprüfung gestellt. Jetzt mit dem Fräser in die Mitte des Lochs fahren und dann vorsichtig mit den Kurbeln zur Seite. Sobald man den Lochrand erreicht hat piepst es. (Die Schneiden vorher in die relevante Richtung drehen!) Damit kann man alle vier Richtungen sauber ausmitteln und den Fräser exakt an seine Startposition bringen. Dann noch 1,4 mm nach vorn, 1,2 mm nach links und 1,4 mm nach hinten fahren. Langloch fertig und passt. Wichtig: Die angegebenen Drehzahlen sind viel zu hoch! Mit denen müsste man >10 mm pro Sekunde fahren, was natürlich nicht geht. Bei weniger Vorschub reibt der Fräser nur und bricht ggf auch noch ab. Bei normalem Handbetrieb (ideal 2mm/s Vorschub, mindestens 1mm/s) muss man die Drehzahl auf Minimum (5000 Touren) stellen. Dann schneidet der Fräser einigermassen richtig. Bei mir kamen keine normalen Späne raus, sondern eher sowas wie "Zuckerwatte". Ein Zeichen dafür, dass der Vorschub noch zu langsam bzw. die Drehzahl noch zu hoch war. Aber es hat funktioniert.

A**A

Puede con más de lo que puedes esperar al verla a costa, eso sí, de realizar más pasadas de menos profundidad. La he utilizado sobre aluminio, latón y acero con buenos resultados sobre todos ellos. De fábrica trae todos los ejes con holgura, es preciso tomarse un tiempo en ajustarlos correctamente. Le he montado rodamientos planos en ambos extremos de los ejes X e Y con lo que se puede apretar un poco más la tuerca del extremo con lo que desaparece por completo el backlash de dichos ejes (es preciso abrir completamente el hueco donde monta de serie una arandela para poder acoger el rodamiento). En el eje Z, con la utilización de los rodamientos se consigue reducir el backlash a unas tres centésimas de milímetro. La he montado sobre una placa de granito (reciclada de un mueble de baño) que aumenta su estabilidad. He instalado un nuevo eje con mordaza er11, mucho más versátil que la propietaria de proxxon.

Trustpilot

Hace 1 semana

Hace 1 semana